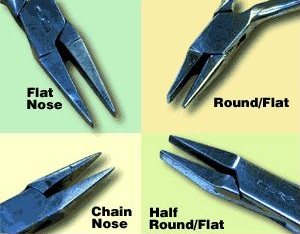

The basic set of pliers for jewellery manufacturing and the first to acquire when setting up a new workbench would be flat-nose pliers, round/flat-nose pliers, half-round/flat-nose pliers, and chain-nose pliers.

Almost all jewellery-making techniques can be executed with these four pliers. These tools are not only suitable for fabricating, repairing, and other types of bench work, but also for finer, more delicate work, such as bead stringing. This is a suitable set for hobbyists, craftspeople, and students.

A silversmith’s work can only be as good as the condition of his/her tools. It stands to reason, then, that tools should not be regarded lightly. Great care should be taken in choosing your purchase and in maintaining their condition.

Observing Tolerance: Choose your tools for the specific reason they were made and never use them beyond their tolerance level. In other words, do not use your pliers in situations that require more pressure than the tool can handle.

Comfortable handling: Hold the pliers in your hand and feel how it fits in your palm. This should be comfortable to the size of your hands. A person with big hands will find it awkward working with short-handled pliers. An option to consider is tools with plastic-dipped handles. These can provide comfortable work for hours.

Tension Springs: Most pliers are designed with a double- or single-leaf tension spring. There are pliers available without springs; however, excellent training goes a long way in the proper handling of such tools. For those unfamiliar with the correct way to hold springless pliers, springs will add ergonomic comfort and resistance control to their pliers.

Precision Tips: Ensure that the jaws of the pliers meet precisely and evenly–and grip and hold an object securely. Some pliers are designed with parallel-action jaws. Such pliers will continue to hold an object, even a round one, securely under increasing pressure without letting it slip forward. Another design is of pliers with one smooth steel jaw and one flat nylon-covered jaw. This is an additional precaution for avoiding marring metal when forming, however, it is not essential.

Jaw Length: Short-nosed pliers are more suitable to working on a small scale. Long-nosed pliers are more suitable to bending silver sheet, as the longer the nose, the greater the reach and the longer the bend.

Tip Size: Pliers come in different tip sizes. Consider the slim line fine-tipped pliers for delicate, detailed work that cannot be done with the heavier, wider tip size more suitable to fabricating and repairing.

Pliers Metal: There are two options available, stainless steel and hardened tool steel pliers. Stainless steel is rust resistant, offering a reasonable bench life. However, the surface condition of the nose has to be monitored and maintained as needed as it will eventually start showing nicks. Stainless steel pliers cannot be forged.

Hardened tool steel is the preferred metal for pliers as it is the hardest, strongest, and longest-lasting material for pliers. These pliers are forged for durability. Work done with these pliers requires less finishing as the nose is not prone to nicking with normal use, therefore producing cleaner work. A major drawback, though, is that the hardened tool steel pliers are prone to rusting. However, taking good care of your pliers, not exposing them to moisture, keeping them lubricated, and wiping them occasionally with a rust inhibitor, such as Cosmoline or WD-40, can deal with this problem.

TIPS ON CARING FOR YOUR TOOLS: Before using brand-new tools for the first time, a good precaution is to prepare the tools first. This is done by using a fine sanding stick to soften the edges of the pliers’ nose. A second step is to shine up the surface of the nose that will be making contact with the jewellery metal. The reason for these two important steps is to ensure that new tools do not accidentally leave marks on the silver during the fabrication process.

Liz Kuhn, G.G. (Reprinted from Jewllery Today online newsletter June 2012).