What gauge of metal should I use? This is a question we get asked at Workingsilver all the time. Unfortunately there is no single answer to this one. It really depends on many different factors: are you making a ring or a pendant; will you be adding texture; are you using sterling silver or copper? While every project is going to require different materials, hopefully this post will provide you with a general guide for picking your metal gauge. This should in no way be considered written in stone, but rather a starting point. (Remember there is always an exception to a rule…and sometimes breaking rules is fun!!!)

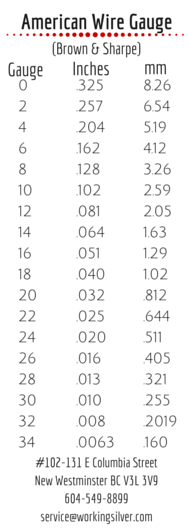

Below is a handy reference chart with the most common metal gauges and their equivalent measurements, both in metric and imperial.

When picking an appropriate gauge for a project the first thing to consider is what are you making. Bellow is a list of gauges that work great for certain types of projects.

Project Metal Gauge

Earrings 22 gauge sheet or 18 gauge to 12 gauge wire

Pendants (design dependent) 18, 20, or 22 gauge sheet

Backing for a bezel 24 gauge sheet OR 22-20 gauge sheet if the back plate is to extend beyond the bezel wire and have texture or embellishments on it.

Rings – wide shank 18 or 20 gauge sheet

Rings – narrow shank 18, 14, or 16 gauge wire

Ear wires and earring posts 20 gauge (1/2 hard wire is highly recommended)

Bangles 8, 10, 12 gauge wire

Cuffs 18 or 20 gauge sheet

Jump Rings 14, 16, 18, or 20 gauge wire

Corrugation 30 gauge sheet

Fold Form 26 or 28 gauge sheet

Remember there are other factors to consider such as adding texture to your metal. If you are adding a hammered texture or putting your piece through a rolling mill with a texture sheet, your metal will become thinner. So start with a thicker gauge than what you want your finished product to be.

The type of metal you are using may also influence what gauge you choose. As with different types of stones, each metal alloy has a different hardness and strength. For example Sterling Silver is much harder than Fine Silver due to Sterling Silver being an alloy. 20 gauge sterling silver wire is perfect for ear wires, but the same thing made out of fine silver will be much too soft and unable to hold its shape. Alternately, gold is much harder than silver allowing for much finer and more detailed designs that will withstand everyday use. Pure copper is extremely soft, but can become adequately hardened for most jewellery requirements.

So remember that these are just general guidelines, and there is always an exception to every rule! Having a broad selection of different gauges of both sheet and wire allows you to create whatever your head can imagine and your heart can desire.