It’s amazing how many wonderful jewellery designs one can create just using Wire Jump Rings!! Kathy’s Marrakesh, O Pendants, and O Rings are just some examples.

Kathy’s designs using Jump Rings of various sizes were made using Sterling Wire. Of course, you can also use other wire: Argentium Sterling, Copper, Brass, or Gold Filled. OR mix up the colours for even more interest – if this suits your design.

When designing your jewelry piece (and ordering wire!), think about the aspect ratio of the links. The aspect ratio will affect the appearance of your rings. As an example, Kathy used 14 ga. round sterling wire for her largest circle and 18 ga sterling round wire for most of the other rings whose inner diameters range from 3-8mm.

What do you need?

- Wire – Kathy used sterling silver, but you can opt for gold filled, argentium sterling, copper, brass, or change it up with twisted or beaded!

- To measure your wire, you’ll need a good Ruler.

- To cut your rings, you will need a Saw Frame and Saw Blades (we recommend #3/0 or #4/0 blades for cutting rings)

- Soldering Set Up – Torch, Soldering Block (we recommend our Silquar Block, because it’s a bit of a heat sink and may prevent melting too many jump rings!), Pickle, and Solder, Pickle Tongs, Solder Pick. Working with jump rings does not need a professional torch set up. Our Buddy Butane or our Mini Butane Torch are small and simple and can be easily set up in a home space. Butane torches are perfect for small projects – like jump rings! No need for large gas cylinders, butane can be purchased at any hardware store, in sizes no larger than your shampoo bottle.

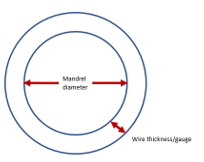

- Mandrels or something to form the rings around. Depending on the size you need, you can use a round bezel mandrel, or a ring mandrel, or vary the design with square or oval mandrels! All these mandrels are cone shape, so when wrapping wire to make jump rings, you are going to get a variety of size rings. This will work well for some designs, but if you want all the same size rings, find a straight (not cone shape) tool. One end of a Dapping Punch can work perfectly for this.

- Use “Dead Soft” wire and tape one end to the tool you’re using for make the wire coil. Hold the wire tight to the mandrel or punch with your fingers while you’re wrapping. Before cutting the wire coil, slide it off the mandrel and wrap it with painters tape. Cut through the tape. The tape will give the wire coil some strength and will hold on to the jump rings as you’re cutting them.

- Our multi-size looping pliers, is also great for forming jump rings 2mm -9mm.

Note: Our round bezel mandrels range from 6mm at the tip to 12mm at the base, square from 3 to 8.5mm, and ovals from about 6mm – 12mm on the longest side. Round ring mandrels range from 12 to 14mm in diameter.

Soldering the jump rings. The type of solder used will depend on the metal you choose and the type of join you are making. You’ll want a good colour match and good strength for each join. For the O ring project, Kathy used sterling rings, soldering them flat on the soldering block with hard silver solder and ended with Argentium easy silver solder after forming the rings for soldering the ends together. Yes, Argentium solder can be used with regular sterling silver – and it’s a fabulous colour match! The rings were then formed on a round Ring Mandrel using a Rawhide Mallet or Rubber Hammer.

And of course, check out our Pinterest page for more jump ring jewelry inspiration! Like this bracelet in the making by Eva Sherman! (https://evashermandesigns.com/)